Applying a quality conscience to safety critical projects

Costain shapes, creates and delivers pioneering solutions that transform the performance of the infrastructure ecosystem across the UK’s energy, water, transportation and defence markets. Here, Martin Davies, their Quality Director, Nuclear, shares five key learnings for achieving success through quality, in environments that are heavily regulated.

The delivery of safety-critical major projects across the infrastructure ecosystem is incredibly complex. Even more so when set against a backdrop of the energy crisis and the government’s drive for efficiencies. It has never been more important that as an industry, we demonstrate respect for the public purse and deliver value to the taxpayer, whilst maintaining the highest standards of quality.

For an organisation such as ours, a key way we can do this is by considering our projects as a portfolio, and rather than delivering them in silo, actively seek to exploit opportunities for sharing knowledge. By implementing a systems approach and examining the synergies between projects in the nuclear and defence, rail and energy sectors, we can turn key learnings into actionable insights. These can be used to redraw the model for successful programme delivery, ensuring that we are delivering value outcomes, efficiently – while never losing sight of the fundamental imperative of assuring quality.

As practitioners in the infrastructure market, we have taken our cross-industry experience from energy, defence and rail, to share five key learnings for achieving success through quality, in heavily regulated environments.

Our vision – what does best practice look like?

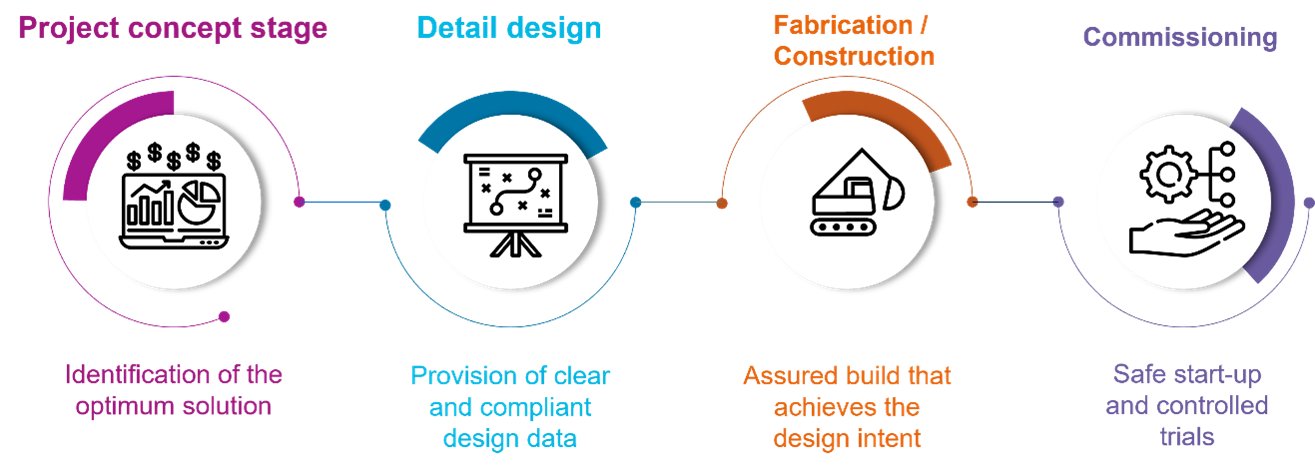

We believe that there are core foundations which have to be in place to assure high standards of quality. In safety-critical projects, the importance of process safety thinking needs to be established and embedded as a culture from the outset and underpinned by a strong quality culture. What do we mean by this? An integrated project team which is defined by a ‘one team’ mentality with a clear vision of what success looks like and the role of individuals in realising it, enhancing decision-making throughout the lifecycle of the project.

‘Production thinking’ and ‘building information modelling’ techniques are at the heart of this vision; a vision of standardisation where we only create bespoke assets where absolutely necessary, where we use data insights to fuel collaborative working and digital rehearsals to maximise the opportunity for off-site assembly, testing, trialling and commissioning.

Our five key learnings

-

Adopt a holistic systems view.

-

Establish and measure culture and behaviours.

-

Embrace the power of digital.

-

Standardise wherever possible.

-

Establish a systems integration facility where the interaction of systems can be fully assessed before onsite installation.

Quality should play an ever more prominent role in transforming the performance of our infrastructure. If a strong quality regime is established at the mobilisation stage of complex major projects, with cross-functional buy-in, we can minimise the risk of unanticipated costs or delays to schedule. Furthermore, by adopting a systems approach which identifies synergies across the whole programme lifecycle, through standardisation and the use of digital tools, we can de-risk the trialling, testing and commissioning of safety critical systems and assure delivery to client expectations. This means eliminating waste wherever possible, while also creating social, economic and environmental value.