The path of continual improvement

Progress indicator

Rasoul Aivazi, a committee member of the CQI’s Audit, Deming, and Digital Transformation special interest groups (SIG) and Chair of the CQI’s Audit and Deming SIG subcommittees in Japan, looks at the convergence of Kaizen, Katana swordmaking and Deming’s quality teachings.

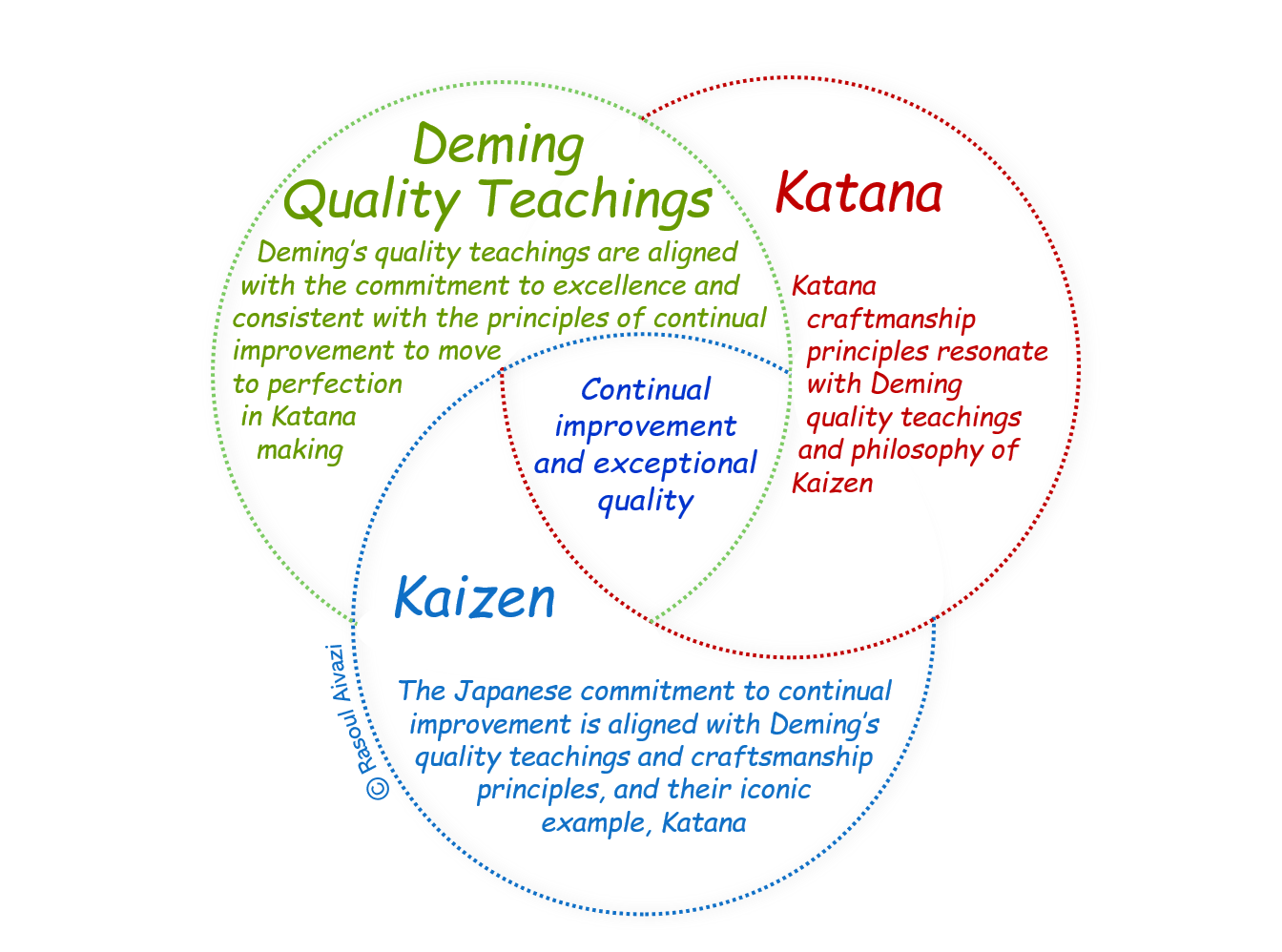

Kaizen refers to the practice of continual improvement or incremental changes for progress. It is a fundamental concept in Japanese culture and business philosophy, involving all employees striving for improvement and driving innovation and efficiency. It is often applied in business processes, personal development, and problem-solving.

Kaizen encourages individuals and organisations to seek better methods, eliminate waste and enhance efficiency. It aligns closely with the dedication to quality in Katana swordmaking, as each fold, each strike of the hammer, represents a step towards improving the quality and performance of the final product (see Part 7 and Part 8 of this series).

Swordsmiths continually refine their ways to improve the quality, durability and cutting prowess of their blades. The quest for excellence in Katana-making aligns harmoniously with the principles of Kaizen, as both share a commitment to relentless improvement and an unwavering focus on achieving excellence.

Deming’s quality teachings: a paradigm shift

Dr W Edwards Deming’s quality management teachings played a pivotal role in Japan’s post-World War II recovery. His statistical quality control methods and the Deming Cycles – Plan, Do, Study, Act (PDSA) and Plan, Do, Check, Act (PDCA) – emphasised the importance of quality management in manufacturing. These principles resonated deeply with Japanese cultural values and the Kaizen philosophy, helping Japanese industries achieve high efficiency and reliability.

Deming’s teachings on quality management also emphasised the importance of statistical analysis, process improvement and customer satisfaction. The Japanese embraced Deming’s principles, recognising their profound implications for manufacturing systems and organisational culture, constancy of purpose, and the inextricable connectivity from supplier through to customer.

Deming’s teachings resonated deeply with the principles of Katana craftsmanship and the philosophy of Kaizen. The core tenets of Deming’s quality teachings, including his 14 Points and the System of Profound Knowledge, aligned with the Japanese commitment to continual improvement and the pursuit of excellence.

The synergy

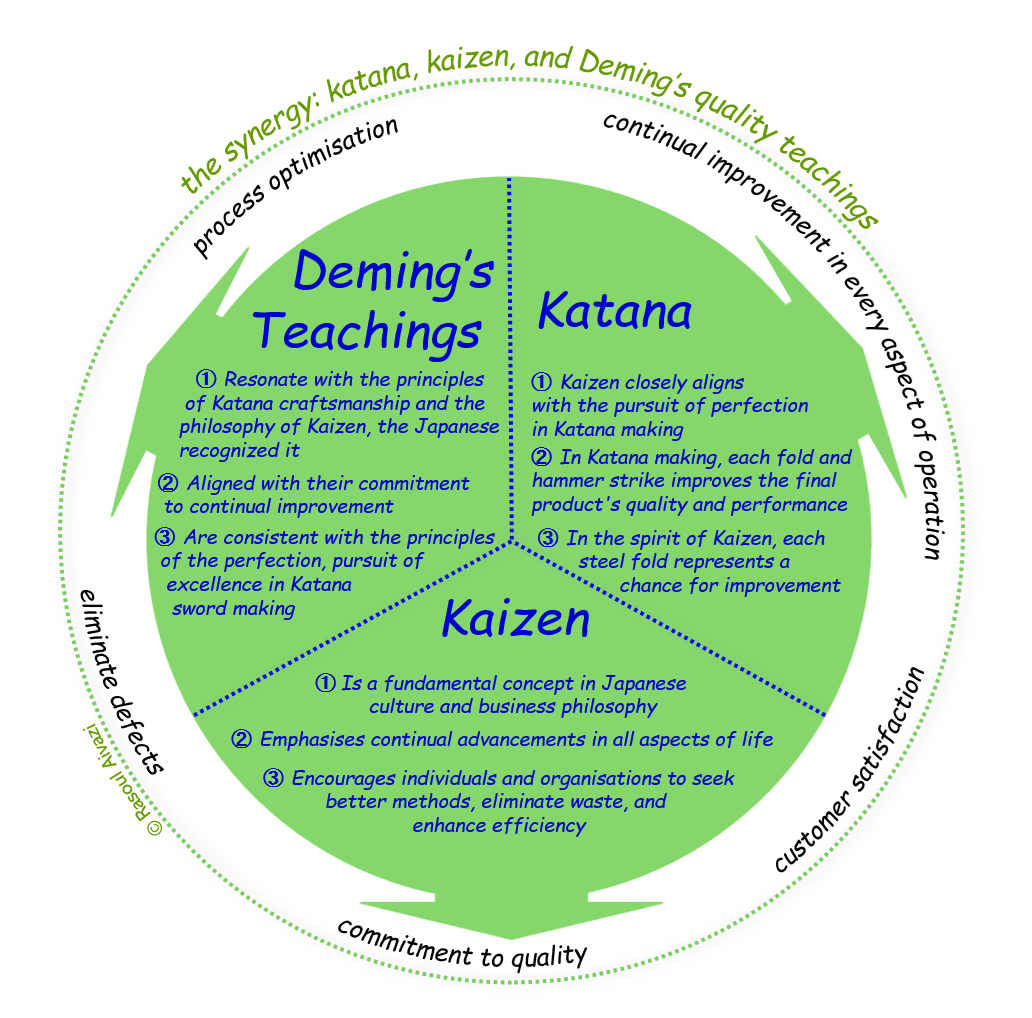

The convergence of Katana craftsmanship, Kaizen and Deming’s quality teachings showcases the interconnectedness of these transformative forces. They share a common thread: the drive for excellence and continual improvement.

This synergy has influenced various aspects of Japanese daily life and technological advancements, making Japanese technologies synonymous with quality and innovation.

Figure 1: Katana, Kaizen and Deming's quality teachings in Japan overlap on continual improvement and exceptional quality.

The correlation between Katana, Kaizen and Deming’s quality teachings extends beyond the realms of craftsmanship and Japanese culture. It has significantly impacted leadership principles, total quality management (TQM) practices, and manufacturing systems worldwide. Leadership practices have been deeply influenced by the philosophies of Katana, Kaizen and Deming.

TQM principles, rooted in the pursuit of excellence and continual improvement, have been shaped by the philosophies of Kaizen and Deming. TQM aims to enhance customer satisfaction by integrating quality into all aspects of an organisation’s operations. The principles of customer focus, process improvement and employee involvement that underpin TQM accord with the pursuit of excellence in katana craftsmanship and the philosophy of Kaizen.

“The correlation between Katana, Kaizen and Deming’s quality teachings extends beyond the realms of craftsmanship and Japanese culture. It has significantly impacted leadership principles, total quality management (TQM) practices, and manufacturing systems worldwide.”

Organisations worldwide have adopted TQM practices, inspired by the Japanese approach to quality management and the enduring quest for perfection exemplified by the Katana.

Summary

The mission of perfection ingrained in the art of Katana swordmaking aligns with the principles of Kaizen and Deming’s teachings on continual improvement, customer focus and process excellence. This convergence has shaped Japanese culture, revolutionised industry practices and influenced organisations globally.

Shifting context, the Katana in modern times holds significant cultural and symbolic value in Japan, representing the spirit, honour and ideals of the samurai, including discipline, loyalty and courage. Its artistry and beauty have captivated people worldwide, with the elegant design and distinctive hamon igniting the imagination of enthusiasts. The Katana remains revered for its historical significance and artistic worth, and the legacy of the katana lives on as its influence extends beyond its physical form.

Acknowledgement: This part of the series has benefited from the review and comments of distinguished international experts: Richard Brett, Hiroyuki Iwamoto (岩本博之), Ryo Kanno (菅野亮), Shinya Watanabe (渡邉慎也), and Toshihiro Koga (古賀稔広). I am also deeply grateful to the officers and committee members of the CQI’s Audit and Deming Special Interest Groups, whose unwavering support and thoughtful feedback have been invaluable. Special thanks to Kenji Oyamada (小山田賢治), whose encouragement years ago first sparked my interest in katana studies, and who also provided meaningful support in that field and its related techniques. I sincerely appreciate the expertise and contributions of all who have illuminated this journey. Any errors remain entirely my own.

Read this series from the beginning

Go back to the start of the Hidden Dimensions series and enjoy each part again, starting with Part 1.

The latest from the CQI Podcast

Listen to the Quality Impact podcast, where experts share insights on the evolving role of quality across industries.

Quality World

Get the latest news, interviews and features on quality in our industry leading magazine.